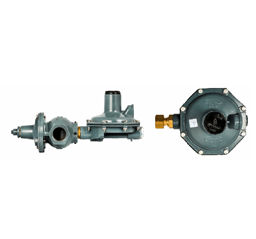

Die Casting

Die Casting Specification

- Material

- Aluminum

- Application

- Industrial Component

- Processing

- Die Casting

- Surface

- Polished

- Machining Type

- CNC Machining

Die Casting Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Main Domestic Market

- Maharashtra, All India

About Die Casting

Molds by Sohum can be made out of materials like Aluminium, Zinc, or other suitable materials that have an ample capacity for a broad spectrum of part shape, and volume. We integrate our engineering and manufacturing capabilities at Sohum Autogas Systems Pvt. Ltd. to streamline project development. We employ engineers who have experience managing all aspects of your die casting manufacturing project. They can consult with your team to improve the quality and decrease the cost of your components. The overall project management of Sohum ensures accurate results and timely completion. Sohum is a successful die casting partner for every project. Our secondary finishing solutions complement our die casting capabilities. The Sohum professionals perform machining, finishing, assembly, and testing on all die-cast projects.

- Automobile

- Agriculture

- Construction

- Industrial Equipment

- Telecommunications

- Pharmaceutical

- Durable, dimensionally stable components.

- It is able to produce complex shapes more precisely than other methods of production.

- It can combine several functions into a single, complex-shaped part.

- Production rates high with little to no machining

- Thinner components can be produced than those produced by other casting methods.

- The plastic injection mouldings are much stronger than alternatives.

- A mass production process allows for the production of thousands of identical castings within specific tolerances.

- Castings in zinc can be easily plated or finished without significantly preparing the surface.

- Surfaces that are smoother than those produced by sandcasting or permanent moulds.

- Various hole sizes can be tapped and cored.

- It is possible to include external threads on parts in the cast.

- Reduce assembly costs by incorporating integral fasteners, such as bosses and studs.

Precision and Versatility in Die Casting

Our die casting process is engineered to achieve exceptional accuracy, with tolerances as tight as 0.05 mm. Clients can choose from a variety of customized shapes and sizes for their industrial components. This level of versatility ensures each part perfectly fits its designated application, regardless of complexity or size within our weight range.

Durable and Reliable Industrial Solutions

Aluminum components produced via our advanced die casting and CNC machining offer superior mechanical properties. Through surface treatments like anodizing and powder coating, each part gains enhanced corrosion resistance and durability. With moulds designed for up to 100,000 shots and robust export-standard packaging, we support high-volume, global demands seamlessly.

Speedy Deliveries with Comprehensive Support

We understand the importance of timely production for industrial projects, offering lead times of just 2-4 weeks. Our support extends from design to delivery, ensuring a smooth, transparent process for distributors, manufacturers, suppliers, and traders. With our base in India, we efficiently serve both domestic and international markets.

FAQ's of Die Casting:

Q: How does the die casting process ensure high precision for industrial components?

A: The die casting process utilizes high-precision molds and controlled environments to produce aluminum parts with a tight tolerance of 0.05 mm. This ensures each component consistently meets exact specifications, ideal for critical industrial applications.Q: What are the benefits of anodizing and powder coating for die cast components?

A: Anodizing and powder coating provide robust surface protection, significantly improving corrosion resistance and aesthetic appeal. These finishing options also prolong component life in demanding industrial environments.Q: When can I expect delivery after placing an order for customized die cast parts?

A: Typically, your customized order will be ready within 2-4 weeks. This includes the time for die casting, CNC machining, finishing, and export-standard packaging to ensure safe delivery.Q: Where are your die cast components manufactured and shipped from?

A: All components are produced and packed in our advanced facilities in India. From there, we handle both domestic and international shipping using export-standard methods to guarantee quality and safety.Q: What quality standards are followed to ensure mould longevity and consistent performance?

A: Our molds are engineered for up to 100,000 shots, utilizing high-quality materials and rigorous manufacturing controls. This guarantees consistent output and reduces downtime for frequent mold replenishments.Q: How is CNC machining integrated into the die casting process for aluminum components?

A: After die casting, aluminum parts are CNC machined to achieve precise dimensions, smooth surfaces, and customized shapes. This integration gives each component a polished finish and exact fit for its intended application.Q: What are the primary industrial applications for your die cast aluminum products?

A: Our die cast aluminum components are designed for a wide range of industrial uses, offering excellent thermal conductivity, strength, and corrosion resistance-ideal for machinery, equipment housing, heat sinks, and mechanical assemblies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS